“Explanations exist; they have existed for all time; there is always a well-known solution to every human problem – neat, plausible, and wrong.” - Henry Louis Mencken, Prejudices: Second Series

Donald Trump has a new favorite word, a magical word, and that word is “tariffs.” Tariffs will Make America Great Again! Trump will stop the Chiiyna with the tariffs!

No, he won’t.

This is an interesting area for me, because among the various companies I’ve worked with was one that managed supply-chain logistical issues for Japanese and Korean companies that were moving factory lines from Asia to North America (mostly Mexico), to take advantage of NAFTA tax breaks. Essentially, we were responsible for the parts necessary for production being on the factory floor when needed: not too early (so they have to be stored both physically in the factories and financially on the balance sheets), and not too late (lest they shut down production). To give you an idea of how tightly these things are run, we typically had a delivery window of 2-4 hours (sometimes as little as 15 minutes) and every mistake or exception resulted in much wailing and gnashing of teeth. Japanese and Korean companies expect things to be done perfectly.

So I spent many years watching the challenges involved here, first-hand. When people think of manufacturing, they seldom consider how much goes into it. You need all sorts of machines and robots, human workers, management, etc. And parts. Lots and lots of parts. It is only a small exaggeration to say that there as many parts used in manufacturing as there are stars in the heavens. Many of these parts fall into an interesting category: they are both indispensably essential and cost virtually nothing, often a very tiny fraction of a penny. If you look at a circuit board in any modern electronic device, it is almost always liberally sprinkled with tiny resistors and capacitors, each not much larger than a grain of sand. There are also screws, brackets, zip ties, cable harnesses, wires and connectors, and countless other things. And virtually all of them have to be made in the relatively poor countries in Asia.

Why? Because that way they cost virtually nothing, and if they don’t cost virtually nothing then the price of whatever you’re making goes up by a lot. In some cases, double or triple. All of these tiny little pieces add up, and then get multiplied by the profit margins necessary at the manufacturing, wholesale, and retail levels. Even making them in Mexico is often financially sketchy. Making them in the US? It’s a ridiculous fantasy, at least for now. It could happen, but with heroic efforts overseen by capable geniuses and backed by mountains of government money it would take at least 10 years. So you can also add in another round of inflation to the cost of getting this done in a timely manner. Even then, you need demand (local factories) so that the part vendors have somebody to sell to and parts are being made based on actual market conditions and not crazy socialized central planning.

So why were companies doing this in Mexico and not the United States? Labor costs were some of it, but the labor costs aren’t that much cheaper in Mexico, at least in the grand scheme of things. What is a lot cheaper in Mexico is the lack of bureaucratic red tape. When stupid and meaningless red tape does exist, it can often be made to go away with a few well-placed bribes. Allegedly. This is something I’ve only heard about and never, ever witnessed actually happening or been personally involved with. I would never.

Another big advantage in Mexico is that you can reliably receive your parts from Asia. In the US, parts get held up in customs at random, and can take up to six months to clear. So you stock more locally, which adds lots of unnecessary costs. Additionally, the US shipping ports are literally run by the mafia (the longshoremen’s unions), and they’ll tie things up if they aren’t each given $300K a year with 18 coffee breaks a day. Yes, for the US West Coast longshoremen the average annual salary is about $195K with another $100K in benefits, for a total compensation package that exceeds many top Silicon Valley engineers and these guys ain’t exactly designing iPhones. In order to avoid the ocean freight mafia, you have to rely on air freight which is many times more expensive and adds lots of unnecessary costs. It’s not just money, but time. If you have a last-minute specification change or receive a bad batch of parts and the replacements aren’t available locally (add more costs for a wholesaler holding the inventory on spec), you have to move them from halfway around the world at ridiculous cost. In China, you move them from halfway across town more or less for free. In Mexico, at least this process is reliable. In the US, you can be seriously screwed (or unscrewed, if the parts in question are screws).

Fixing US customs could probably be done with an executive order, but nobody’s even mentioned it. Breaking the longshoremen’s unions and automating the ports will take a huge amount of political capital and many years of investment (there is plenty of private funding for this, but they’ll screech for government money if they think they can get it) and physical construction. It’s another 8-10 year project. Asia’s ports are already heavily-automated for the most part. Fixing the insane amount of overregulation in US manufacturing is another huge task, and I’m not aware of anyone who has even dared to dream big enough to build an actual plan for this. Figure a minimum of 2 years for planning, passing, and implementing it – and this is just a guess.

Once you get past the physical logistics of making things in the US, there’s an even bigger problem that we’re faced with. Big American corporations are burdened by tons and tons of internal management retardium. It’s not Chiiyna’s fault that Boeing builds airplanes with parts that aren’t bolted on and space capsules that leak all over the place. It’s not Chiiyna’s fault that DEI and ESG have taken over American corporate culture. It’s not Chiiyna’s fault that corporations are run by MBAs that think everything important is a number, and that the solution is always some weird fad like Matrix Management or some new process certification. Most of this can be blamed on academia, and we haven’t even begun to deal with the academia problem.

It’s not Chiiyna’s fault that labor unions have way too much power. It’s not Chiiyna’s fault that the EPA and FTC and SEC and dozens of other alphabet agencies will fuck your shit up because their perfectly secure government jobs give these pissants an endless series of anthills to piss on us from, whenever they feel like it. And so on, and so on, and so on.

This reflects some of the work necessary to bring manufacturing back to the US, and it’s just the part that I’ve seen firsthand. I can guarantee there’s a lot more that I haven’t seen. And I agree that China’s government is evil and repressive and it would be nice if it went away and left the world, and especially the people of China, alone. But the ugly truth is that the reason manufacturing went to China isn’t just price. It’s because you can get things done there. You can get things done, to a certain extent, in Mexico. Getting things done in the United States is an absolute nightmare. The Democrats love the control. The Republicans love the money and power they get by promising to fix things and then endlessly failing (if they fix things, then the gravy train goes away). Trump talks about some problems, but never does any actual homework. He’s a talker, not a doer. That’s fine for a CEO position, but as a CEO you have to be able to back up your promises by finding the doers and giving them the tools they need to work with. Trump’s “dream team” in 2024 is, aside from Musk, nothing more than another gaggle of talkers. Musk is still a talker, but as a CEO he has a track record for putting together great teams of doers. At least in the business world. This doesn’t necessarily translate into politics. It just means, that unlike the others, at least he has something of a clue and maybe some hope of success.

In the meantime, we’re stuck with the neat, plausible, and wrong solution of tariffs. Why wrong? Because if Trump places import tariffs on finished goods from China, all China has to do to cut his magical solution off at the knees is place export tariffs on components and subassemblies. You can’t manufacture stuff out of happy thoughts and cheerful dreams. You need parts. Lots and lots of parts. We need domestic demand for these parts before we can build the endlessly complex and intricate supply chains here to serve them, unless you believe that socialism works. This means fixing our major bottlenecks (mainly customs processing and the shipping ports), and gritting our teeth and making nice with China in the meantime. Yes, it would hurt China badly to knock out the US economically, but make no mistake that they absolutely can do it. They can survive this far better than we can. I’m not even getting into the nation-level financial and currency issues, where they also hold many of the cards. If the pain of taking the US economy out becomes less than the pain of dealing with the US government, the US economy will be nuked and it will take decades of extreme recession / depression to rebuild. This the reality of Trump’s tariff dream, taken to its conclusion.

Don’t worry!

His “very smart people” are totally right about things this time when it comes to trade.

There is zero - I repeat, zero - moral difference between the people who pushed for "experimenting" with lockdowns because "we have to do something!" and the people who push for "experimenting" with trade wars because "we have to do something!"

Musk is out.

Musk put himself in a corner where he can't rip into Trump and he has to play nice probably at least through the midterms, but just look at the guy's face and watch him refuse to give a straight answer here. He put a lot on the line with endorsing Trump and starting DOGE, and Trump absolutely stabbed him in the back. Trump's supporters will blame congress, but Trump has very openly and loudly endorsed all of the DOGE-defying moves that congress has made, and has viciously attacked the one congressman (Thomas Massie) who has stood against it.

The reason is simple: Trump cares about trophies. Cutting the budget is not a trophy. DOGE trying to take a chainsaw to government was a trophy, but as soon as DOGE became more of Musk's than Trump's trophy, Trump stopped caring about it because congress offered him a Big, Beautiful Bill as a trophy instead. Just like the FBI offered the opportunity to build a Big, Beautiful new headquarters building for them (Trump loves buildings!). ...

As comedy slowly slides into unfunny wokeness hell, the last comedian standing (assuming he doesn't drop dead first, I mean just look at the guy; he's a trainwreck) will be Doug Stanhope. He closed out his recent special "The Dying of the Last Breed" with this bit on how important it is that we be able to make fun of anything. Because making fun.

Language warning, duh.

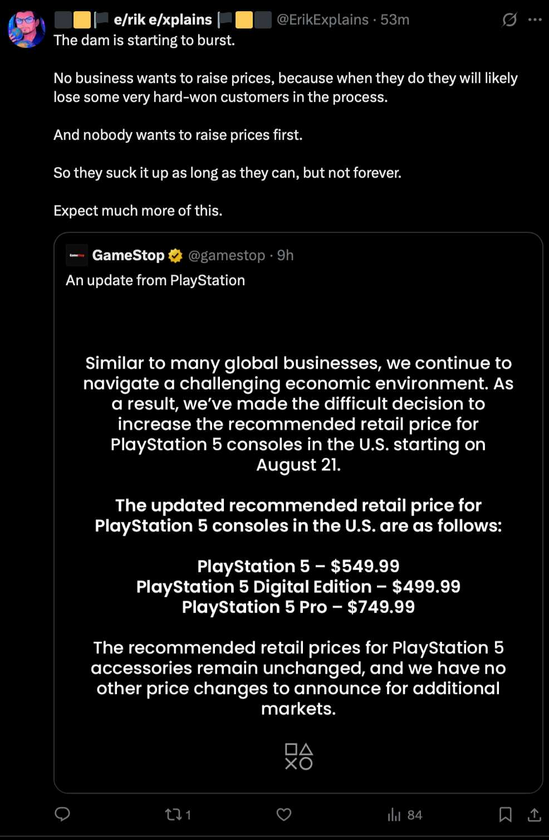

Nintendo raised prices earlier this month, but I would aruge that they're kind of a separate market (handheld, low-power vs. high-power television-based gaming).

And it's not just raising prices or being first to raise prices - if Trump changes his mind and tariffs go back down, then you have a bunch of cranky customers who paid a higher price and some want refunds and then you're out the money. It really is a no-win situation for vendors.

So they put off raising prices for as long as they can, but sooner or later the piper must be paid.